Interlocking Sheet Metal Joints - Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure. Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the.

Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure.

Interlock joints are formed by interlocking the edges of two or more metal sheets. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Here’s an overview of how to join sheet metal without using fasteners. The clinched joint creates a secure.

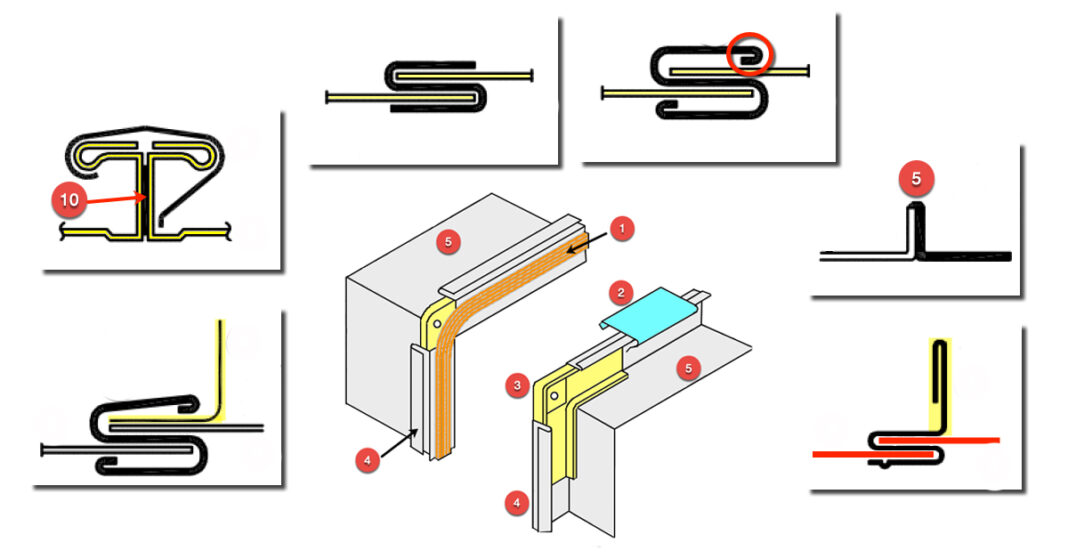

Sheet Metal Seams MEP Academy

Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure. Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the.

Flexible Interlocking Steel Joint System 7 Steps Instructables

While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Here’s an overview of how to join sheet metal without using fasteners. The clinched joint creates a secure. Interlock joints are formed by interlocking the edges of two or more metal sheets.

sheet metal joints Google Search Sheet metal fabrication, Sheet

Here’s an overview of how to join sheet metal without using fasteners. The clinched joint creates a secure. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Interlock joints are formed by interlocking the edges of two or more metal sheets.

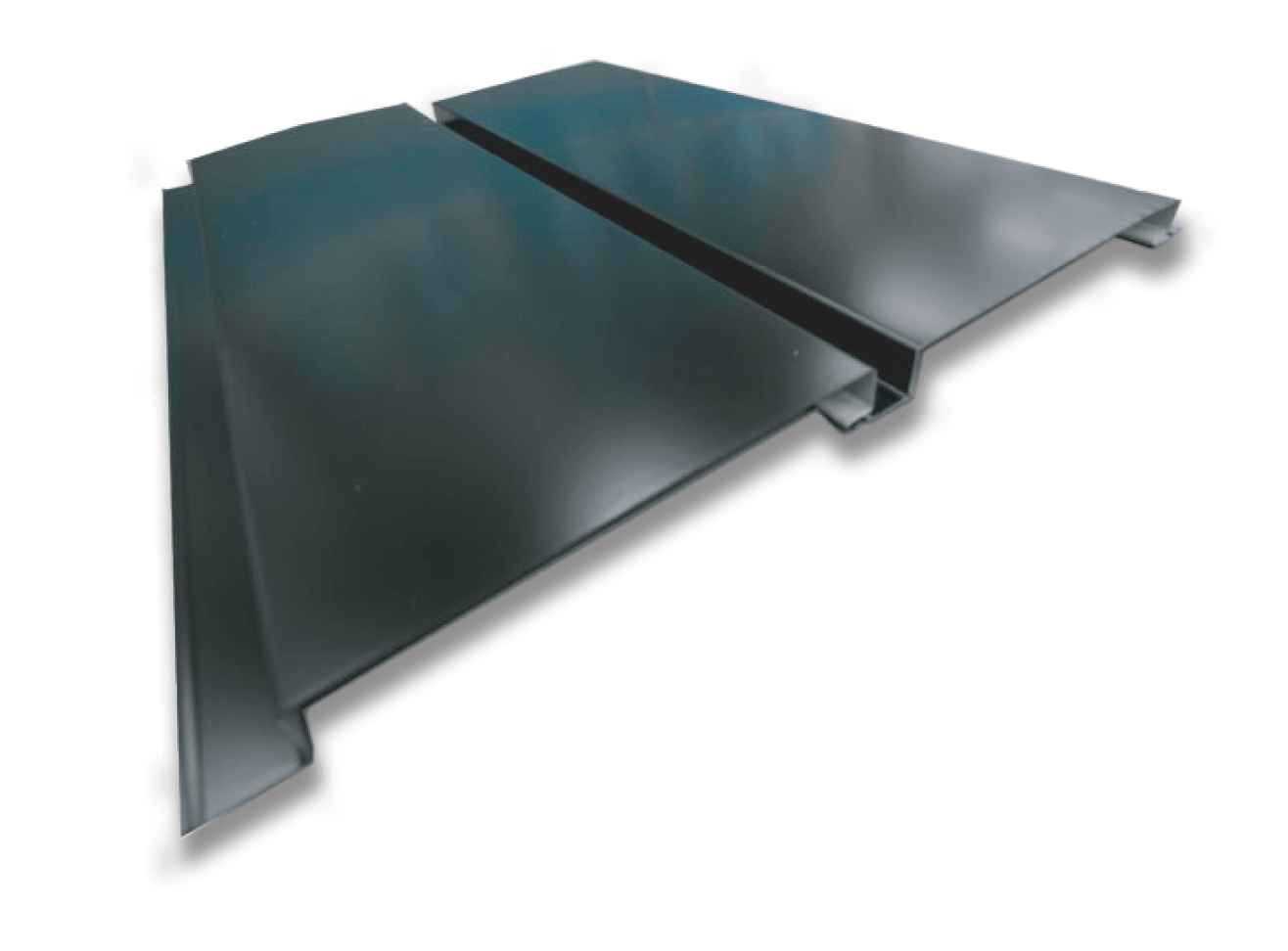

Interlocking Panel Industry Cladding

Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. The clinched joint creates a secure. Interlock joints are formed by interlocking the edges of two or more metal sheets.

Pin on Скамейки

Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure. Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the.

MAC Interlocking Panel Metroll Architectural Collection (MAC)

Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure.

Sheet Metal Joints MEP Academy

Interlock joints are formed by interlocking the edges of two or more metal sheets. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Here’s an overview of how to join sheet metal without using fasteners. The clinched joint creates a secure.

three different angles of a metal table with one open and the other

While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. Interlock joints are formed by interlocking the edges of two or more metal sheets. Here’s an overview of how to join sheet metal without using fasteners. The clinched joint creates a secure.

Flexible Interlocking Steel Joint System Joinery, Jets and Steel

Interlock joints are formed by interlocking the edges of two or more metal sheets. The clinched joint creates a secure. Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the.

The Experimental Analysis of Forming and Strength of Clinch Riveting

Here’s an overview of how to join sheet metal without using fasteners. Interlock joints are formed by interlocking the edges of two or more metal sheets. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the. The clinched joint creates a secure.

Interlock Joints Are Formed By Interlocking The Edges Of Two Or More Metal Sheets.

The clinched joint creates a secure. Here’s an overview of how to join sheet metal without using fasteners. While the basic concept of clinching involves deforming the metal sheets to interlock and form a joint, there are various techniques within the.